|

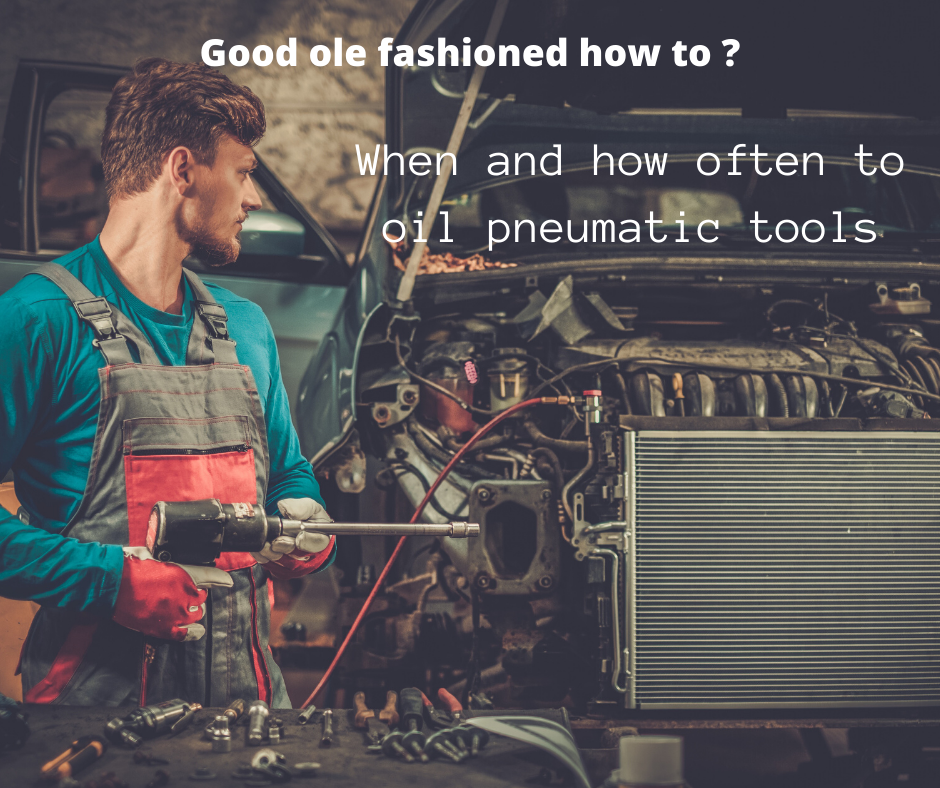

Lubricate the Air Fitting

Squeeze 4-5 drops of pneumatic (Airomatic) tool oil into the air fitting daily. If the tool is used all day, repeat the process halfway through the day. If the tool is not used very often, just oil it when the tool is used. Don Wambach professional mechanic for over 45 years. Airomatic Tool Oil designed to enhance the life of pneumatic tools and their technicians. proper-care-and-feeding-of-pneumatic-tools credit Aviation Pros

The Importance of Oiling

It may seem like a no-brainer, but pneumatic tools require regular oiling and lubrication. Without this degree of care, the parts inside will start to grind against each other. Eventually, the tool will erode itself into uselessness. Amazingly, “we’ve seen many tools at our repair center that have never been oiled: Never,” says Johnson. “This actually happens, even though almost all the air tools we sell say ‘oil daily’ right on the housing. All technicians know the need for grease and oil in automotive applications, yet a few of them don’t see the need in their air tools!” “For all air tools, a lack of grease and oil probably accounts for most damage,” says HECAT’s Matis. “ The only other factor that consistently causes damage is water in the air line.”

0 Comments

|

AuthorRabbitrail Supply Out on a Limb, Lowering and Raising pulley system for hanging bird feeders

$27.99

Out on a Limb, Out on a Limb, Lowering and raising pulley system for hanging bird feeders, yard ornaments, and solar lighting, easy to install and use. BENEFITS: A convenient way to assist you in filling your bird feeders, detouring wildlife from feeding, heightening bird feeders for bird safety, and keeping bird feed dry and away from sprinklers. A boasting best seller and efficient way to hang your bird feeders, keeping you off ladders and chairs. Hang specialty feeders, Oriole feeders, and Hummingbird feeders, at bird-desired heights. 👍 It's the most practical ❤️ purchase you will thank yourself for this year! ⭐️ Our Reviews Stand behind it! See Below ☟ ▶️ Out on a Limb kit includes: · 30ft of pulley line: (American-made 550) paracord · Feeder attachment carabiner-hook · Tree-friendly Branch strap with a Marine Grade Brass & Nickle plated pulley · Marine Grade Black PVC cleat and screws, for quick tie-off, · Easy instructions, plus YouTube Tutorial links. 🆓 Free Shipping on orders over $35.00 Perfect Gift for Backyard Bird Lovers available seasonal holiday gift options. Disclosure: Why Squirrel Proof with Cable? If you have (smart) squirrels in your yard we recommend purchasing Squirrel Proof. The little darlings may nibble and bite through the paracord over time, crashing your feeder to the ground. (fraying the paracord) We hang 7 feeders by the pulley system, Out on a Limb in our yard, only one has been compromised by (smart) squirrels. They do not bother the other feeders. Go Figure??? My original Out on a Limb that Don created for me has been hanging in all manner of weather, since 2015 just outside my office window. Recommended weight restriction, 20 lbs. for easy handling. From our Backyard to Yours; it all began when I asked my husband to hang a hummingbird feeder outside my office window. Convenient pulley system and the perfect height to enjoy my little hummers while working. Currently with seven feeders in our yard, I figure if you pay to feed them you might as well enjoy seeing them from the windows you spend time looking out. The original design has faithfully served me since 2015. Hanging in neighborhoods all across America! Thank you for purchasing directly from RabbitrailSupply.com Home of Out on a Limb Pulley System Questions: [email protected] Categories

All

Distracted by My Backyard Birds | Organic bucket hat

$27.00

That's me! I am distracted by my Backyard Birds! We spend hours enjoying our yards and their feathered friends. Make a stylish and eco-friendly choice with the organic bucket hat! This 100% cotton twill hat, protects your head from the elements; has the potential to become a favorite in your wardrobe thanks to its breathable material and clean look. This product is made especially for you as soon as you place an order, which is why it takes us a bit longer to deliver it to you. Making products on demand instead of in bulk helps reduce overproduction, so thank you for making thoughtful purchasing decisions! Bird Lover Happy Birthday Gift Box | Best Selling Out on a Limb, Seed and Nut Ornament, Personalized Greeting Card, Old Fashioned Sweets.

$49.99 - $89.99

Hey, bird-lover's fam! Do you want to gift your feathered friend a birthday surprise that'll get their wings flapping? Don't worry, we've got you covered with our Personalized Gift Box - The ultimate birdie treat! This box comes with all the avian goodies - the fantastic Out on a Limb pulley system to make hanging bird feeders a total breeze. Plus, your winged buddy will go nuts (literally) over the Seed & Nut Ornament that comes along with it! And don't forget the Personalized Greeting Card to add a touch of birthday greeting, and some sugary sweets to sweeten the deal. Order by 3 pm and we'll have it out the door by 5 pm - just in time for their special Happy Birthday Day! Your special someone and their feathered friends will be chirping your praises for years to come. 👍 It's the most practical 🎁 purchase you will thank yourself for this year! ⭐️ Our Reviews Stand behind it! See Below ☟ ▶️ Perfect Gift Box for Bird Lover | Best Selling Out on a Limb, Seed & Nut Ornament, Personalized Happy Birthday Card, Old Fashioned Sweets. Shipped to their door to celebrate their special day. Gift Box Variations: Regular Out on a Limb, Squirrel Proof, and Bear Proof, please see individual listings for more details. 3 Birthday Card Variations & Sayings: .: Nature Lover Waxwing: "Wishing you a day filled with love, joy, and all the amazing things life has to offer." .: Happy Birthday, Hummingbird: "May your journey through life be filled with success, love, and happiness. Enjoy every moment of your special day. .: Festive Bird Party: May this special day bring you joy and happiness. Gift Box Includes> 1 Best Selling Out on a Limb Pulley System Kit (hanging in neighborhoods across the country) See individual listing for details. 1 Seed and Nut Ball Ornament 4in. diameter, A decorative treat with two premium blends that will draw a wide variety of favorite birds. No waste, no mess, no melt. Great for year-round bird feeding. 1 Personalized Handmade by viaK Valentine Greeting Card signed, sealed with an envelope sticker. (1 Enclosed Thank you Card.) ✍️ Card Greeting: "I love the way you love me." Waiting for us to sign your greeting inside. .:Packaging, Card, Envelope with sticker, Ornament wrapped in cellophane, raffia bow, and twine hanger. OOAL Kit. Sweets: individually wrapped candy. 6 Sweets: Solid Premium Milk Chocolate individually wrapped and Festive butter mints. Sent to the Shipping Address provided. FREE SHIPPING! If your 🎁 gift-giving checklist includes a wild bird lover in your family this is the perfect and highly practical gift that they will enjoy for years to come. Don't just take our word for it, check out our glowing reviews! *Order Today: Please allow the appropriate shipping time from our house (Corvallis Oregon) for your gift to arrive on their doorstep to celebrate that special occasion. *No returns or cancelations on personalized packages. *Standard Greeting: Happy Birthday Day to you and your feathered friends from (Buyers name) Thank you for allowing RabbitrailSupply to put that special bow on your Birthday gift-giving plans. 🏡 Disclosures: If you have (smart) squirrels in your yard I would recommend purchasing Squirrel Proof. The little darlings may nibble and bite through the paracord over time, crashing your feeder to the ground. (fraying the paracord) We have 7 feeders hung by the pulley system, Out on a Limb in our yard, only one has been compromised by (smart) squirrels. They do not bother the other feeders. Go Figure??? My original Out on a Limb that Don created for me has been hanging in all manner of weather, for seven years just outside my office window. YouTube videos Available https://www.youtube.com/@rabbitrailsupply2109 Hanging in neighborhoods all across America! Distracted by My Backyard Birds | Dads Favorite Baseball hat

$23.00

Distracted by My Backyard Birds | Dad's Favorite Baseball Hat.

All hat hats aren't just for dads. Perfect for a Lady's ponytail day. This one's got a low profile with an adjustable strap and curved visor. Great to protect you from the elements. A classic design sure to be your go-to cover. A Rabbitrail Supply Exclusive just for our Out on Limb customers. • 100% chino cotton twill • Green Camo color is 35% chino cotton twill, 65% polyester • Unstructured, 6-panel, low-profile • 6 embroidered eyelets • 3 ⅛” (7.6 cm) crown • Adjustable strap with antique buckle • Blank product sourced from Vietnam or Bangladesh This product is made especially for you as soon as you place an order, which is why it takes us a bit longer to deliver it to you. Making products on demand instead of in bulk helps reduce overproduction, so thank you for making thoughtful purchasing decisions! Cork-back coaster LOVE Out on a Limb | Bird Lover Gift

$6.00

LOVE Out on a Limb pulley system to hang my bird feeders. What a revelation, I'm a Fan! This cork-back coaster is a perfect match for your favorite mug! A thoughtful gift for the Backyard Bird Lover. Create a homey feel while protecting your coffee table or nightstand from mug stains and moisture. The coaster is waterproof and heat-resistant, designed to last a long time. Buy it for yourself or as a lovely gift for your friends and family.

• Hardboard MDF 0.12″ (3 mm) • Cork 0.04″ (1 mm) • High-gloss coating on top • Size: 3.74″ × 3.74″ × 0.16″ (95 × 95 × 4 mm) • Rounded corners • Water-repellent, heat-resistant, and non-slip • Easy to clean The displayed price is for a single item. This product is made especially for you as soon as you place an order, which is why it takes us a bit longer to deliver it to you. Making products on demand instead of in bulk helps reduce overproduction, so thank you for making thoughtful purchasing decisions! Archives

January 2024

Bear Proof | Out on a Limb Pulley System for Hanging Bird Feeders

$67.99

Bear Proof - Out on a Limb, Lowering and raising pulley system for bird feeders, easy to install and use. This a convenient way to assist you in filling your bird feeders, "detouring" BIG wildlife from feeding, and heightening bird feeders for bird safety. The best and most efficient way to hang your bird feeders. Hang specialty feeders, Oriole feeders, and Hummingbird feeders, at the desired height. As you can see from our customer response, Bears are extremely persistent when you hang yummy bird feed outside. They will shimmy up the tree. They may shimmy out on the branch you have hung Out on a Limb from. Swiping it, again and again, to spill the seed. They may break the branch you have hung it on. They may leave it alone and you can celebrate your victory. Our current testimony is, Out On a Limb Bear Proof, the cable system has not been broken. This is a custom-made order. Please See: Bird Lover Gift Options available seasonal holiday gift options. We love our bird feeders and determination is in order when dealing with wildlife, especially the Big Kind! Keep Safe! Bear Proof Out on a Limb Kit includes: · 1 Bear Proof Out on a Limb Custom Kit - 30 ft. of cable (480 lb breaking strength stainless steel vinyl coated cable) · Feeder attachment carabiner-hook · Tree-friendly Covered Cable strap with Zinc Plated pulley 2 Marine Grade PVC Black Cleats and screws 🆓 Free Shipping on orders over $35.00 DISCLAIMER Sorry, No Returns on Custom Orders. Standing behind our product: In the face of a Persistent Bear, only 1-time replacement for broken parts is offered. We conceded nature won! .: PVC-covered cable is less pliable than paracord used on Original-Out on a Limb. Please step out from standing directly underneath the hanging feeder to allow the pulling of the free-flowing cable line to roll over and through the pulley mechanism. Hanging in neighborhoods all across America! Airomatic Tool Oil for pneumatic tools | Environmentally Healthy

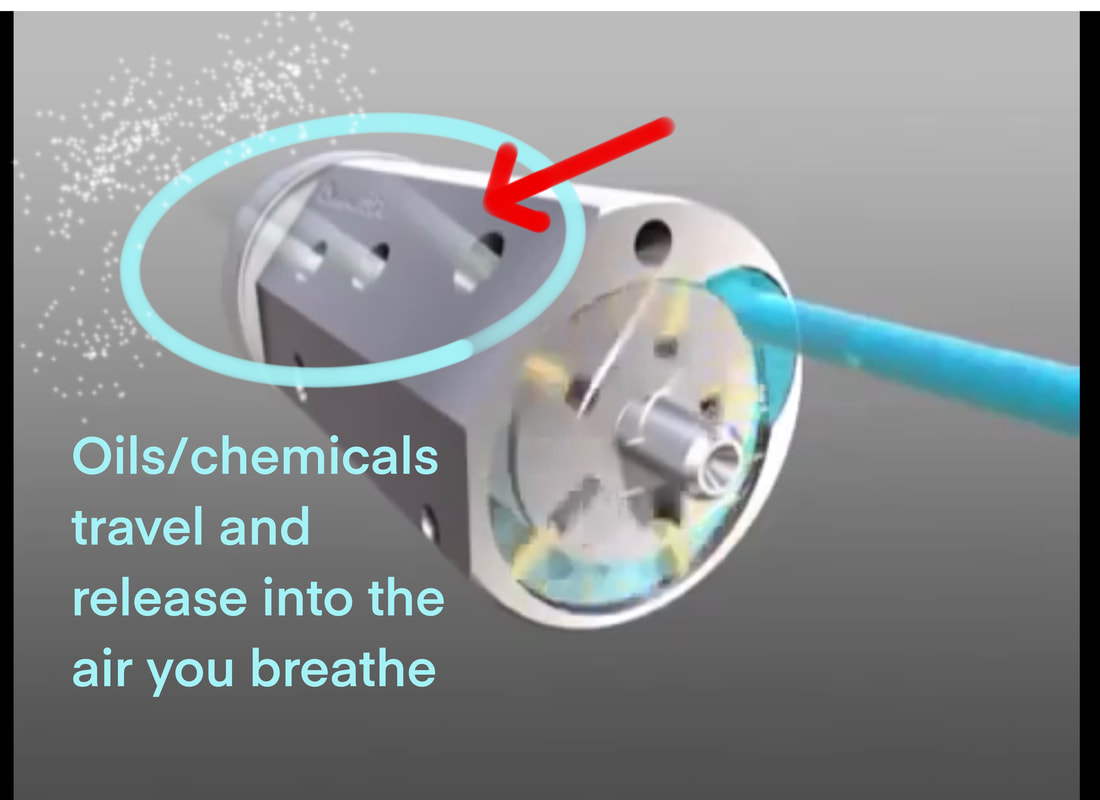

$13.99

Airomatic Tool Oil: Designed by a professional mechanic to enhance the life of pneumatic tools and their technicians. Environmentally Healthy, Quality mineral oil infused with essential oils to diffuse and purify the air. Used by mechanics, carpenters, Roofers, and Home Improvement! Breathe Better! It just makes good sense. Breathe Better! You Will Recieve 1- 5oz bottle of Environmentally Healthy Oil See Blog Post for detailed information and how often you are to oil your pneumatic tools. Tie it Off - Sea Dog Open Base Marine Grade 3 in. Black Cleat | kayaks, canoes, small boats and backyard projects.

$9.50

Tie it Off - Sea Dog Open Base, nylon, Marine Grade 3 in. Black Cleat package of 4. Set sail with confidence and style with the "Tie it Off - Sea Dog Open Base," your premier companion for securing your vessel with unmatched ease and reliability. Crafted from the highest quality marine-grade nylon, this sleek 3-inch black cleat is not just a functional necessity; it's an extension of your boat's character. The "Tie it Off - Sea Dog Open Base" cleat boasts an open base design, allowing for quick and efficient line handling and securing, so you can focus on the journey ahead rather than fumbling with knots. Imagine the “Loose Ends around the yard you could secure” RabbitrailSupply.com “Tie’s Off” top selling Out on a Limb pulley system for hanging bird feeders. But that's not all: cleats are perfect in the home to “Catch all the Clutter” Open a drawer or tie off those string lights. Whether you're docking at a serene marina, braving the open seas, or wrangling backyard projects, the "Tie it Off - Sea Dog Open Base" cleat is your trusty partner in every adventure. Cleats are used on kayaks, canoes, and small boats for controlling steering, seating, and sails. It's more than just a cleat; it's a symbol of safety, durability, and style. Embrace the call of the sea with confidence, knowing that your vessel is secured with the finest because every captain deserves peace of mind as they navigate the vast blue. |

RSS Feed

RSS Feed